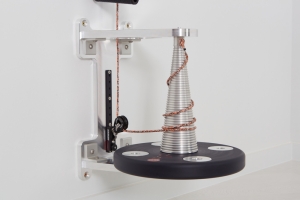

RSP CONIC

The Ultimate Pulley Workout Machine

About RSP Conic

Our conical pulley is designed to train precise movements.

RSP Conic machine is our machine designed to be able to train precise movements involving small muscle groups.

Rotators, shoulder or hip, unipodal work, core work, technical gestures in which we look for high accelerations followed by an intense breaking phase of a body segment… RSP Conic is designed for all this, its axis allows high accelerations with low force applications, making it possible to reproduce precise sports gestures without making the mistake of hanging from the rope.

This precision and progressiveness also allows it to be introduced at very early stages in the readjustments of injuries, since its response to very low force applications facilitates the generation of appropriate stimuli that accelerates the readjustment process and allows the athlete to mantain his or her level of form throughout the process.

How to Adjust Our Isoinertial Pulley

Conic pulleys have two types of load settings that will vary the machine’s response to the athlete’s application of force:

-Varying the moment of inertia: the moment of inertia is defined as the minimum value of force that the athlete has to apply to vary the machine´s state of rest, this means that the higher this value is, the more force the athlete has to apply to start and stop the machine, and the more time he will need to stop the machine and start it again (slower the Eccentric/Concentric transition)

– Varying the axle radius: the conical axle in an inertial machine has the same objective as the gearbox of our car, to facilitate the ability to accelerate with the same application of force. As we raise the position of the rail and reduce the radius of the axis, we reduce the capacity to accelerate the machine, making the movement slower and this allows us to increase the time of tension during the exercise.

To find out more about this, see our article

HOW TO USE RSP CONIC?

With this machine you will be able to perform multitude of excercises for both the upper and lower body, thanks to its hand and ankle grip, the most important thing to perform it well is to adjust the lenght of the rope to our position. The rope should always stop when we reach the end of the movement, avoiding that the rope runs out of tension during our execution. In order to get coupled, we have two options: either we move closer if we want a longer route, or we modify the lenght of the rope until we notice that the rope stops at the end of the route (final concentric phase).

This is the key point to getting the most out of our inertial machine.

TECHNICAL SPECIFICATIONS

| Size: | 45 x 35 x 45 cm high. |

| Weight: | 14 kg. |

| Accessories: | – RSP Encoder – Stainless steel masses – High load pulleys (high performance with high working densities) – Adaptor for Chronojump codificator – Portability kit (to fix the machine to a solid structure such as goal, trellis, column..) |

| Adaptations: | Customization for specific trainings. |

| Spare parts: | – Wall rail pulley – Chassis pulley – Rope (4 meters) |

| See spare parts and accessories: |

Inertia Moments

| Without masses: | 531,39 Kg/cm² |

| 2 masses: | 635,13 kg/cm² |

| 4 masses: | 738,86 Kg/cm² |

| 2 masses Stainless +60% | 829,37 Kg/cm2 |

| 4 masses Stainless+120% | 1126,22 kg/cm2 |

| 2 masses stainless/2 alum +80 % | 933,11 Kg/cm2 |

STANDARD EQUIPMENT

– RSP Conic chassis

– 120cm wall rail for height adjustment of the output pulley

– Ground anchorage eyebolt for vertical shooting

– 4 aluminium masses

– Carbo Harken pulley 40mm Ø

– Carbo Harken pulley T2 Loop 40mm Ø

– 4 meters of high performance rope with length regulator

– Hand grip and ankle strap

– Assembly manual

– Wall mounting kit