ABOUT US

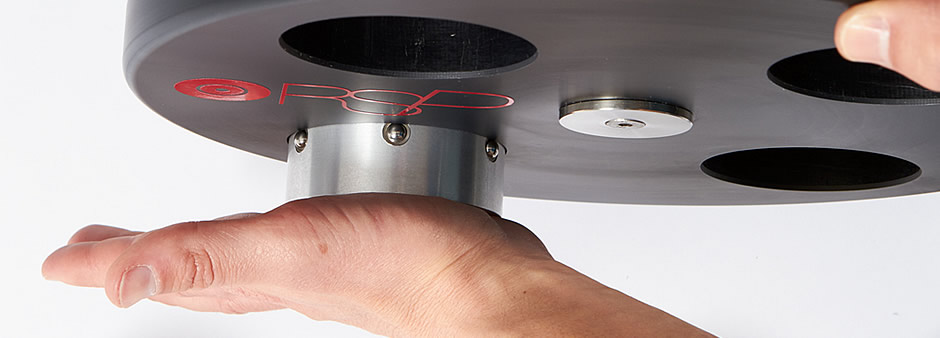

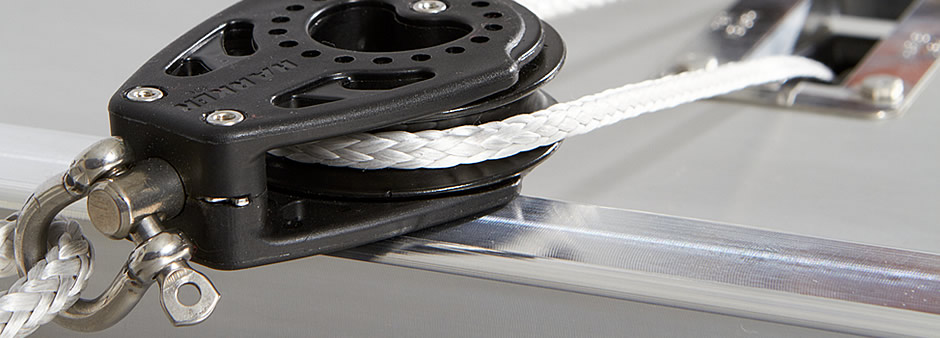

RSP was born in a context of high-performance sports competition and with high involvement of technology (ropes and nautical pulleys). In this context, we got to know the first inertial training machines and we project our experience on them. We quickly realized that applying contemporary technologies in cad-cam design and numerical control manufacturing could greatly improve quality and that is how RSP was born.

We are a team of high grade professional that design and manufacture very high quality parts to improve the performance of our athletes and provide the trainer with the best tools to develop his work,that is our goal as acompany.

Mission

Inercial Performance was born with the mission and objective of designing the best inertial training machines on the market.

We were born and developed in a line of technological application where we incorporate, test and adapt everything that represents an advance and an improvement in our products.

Service

We work by and for people by providing high-quality, simple tools that add value to the training and rehabilitation process.

These tools allow for a level of customization unique to the inertial technology market.

PRINCIPLES OF RSP INERTIAL PERFORMANCE

Inertial performance revolves around quality and simplicity as a goal to develop every day, we are tremendously non-conformist and we know everything can be developed in the line that we like, quality machines, simple and easy to use.

Quality

Thanks to the human team that has been part of this project in many ways, we have managed to incorporate the means and methods of design, analysis and manufacturing from the most advanced industries, such as the automobile and nautical industries. Thanks to these synergies, all the components of our machines have been analyzed and selected with defined performance criteria, achieving a smooth operation and level of our machines that has not existed until now.

Simplicity

We see it so clearly that we have decided to use the best possible components, such as that our machines must be as easy to use as possible, light and adaptable to be used in any space in a simple way. Another value is the possibility of registering the athlete’s work without complications or additional material. Simplicity is one of our main values.

Ease

The different components mean that our machines can be attached to various accessories and implements to adapt them to any sport simply with a clip. For example, we can vary the moment of inertia of our machines safely without tools, quickly and safely. Robust and very high quality parts to achieve personalized configurations and adaptable to any level of training.

OUR WORK PHILOSOPHY

Inertial Performance revolves around training, retraining and performance, in a process of continuous improvement from the base, dedicating and seeking the best performance in every detail. This approach has led us to drink from sources far removed from sport in order to apply processes and systematization to our design, test and manufacturing process, seeking the best product-performance-cost balance. In this way we are sure that we offer the best products at the best price, because we have a live development system that adapts day by day to the changes and needs of each person.

Product

We are proud of our inertial machines, and we want to continue being so for a long time, this leads us to the obligation and need to seek and maintain a line of continuous improvement, analysis and testing, an attitude that allows us to be at the forefront of the design and manufacture of this type of material. Our products are the result of long I+ D+I processes, the essence and philosophy of our company.

People

We work for people and facilitate the work of the trainer, physiotherapist or retrainer. Our field and day-to-day work with our products allows us to know and be aware of the demands of both physiotherapists and trainers and what their clients are going to demand, forming the fundamental pillar on which the process revolves. development of our product, meet the demands of trainers, physiotherapists and retrainers and meet the needs of each person.

Cost

Incorporating the most advanced and current industrial processes in other sectors such as the automotive industry, allows us to offer very high quality and homogeneity standards in our machines, the ability to adapt and modify our products at the rate that sport evolves.

Our structure allows us to be very competitive and offer a high quality-price ratio using automation systems, serial production by numerical control and Cad-Cam tools.

HISTORY

RSP was born completely by chance as a result of my passion for competing and the sport of sailing, inertial machines intersect in my life finishing the Master of the Spanish Olympic Committee in High Performance and starting my Doctoral Thesis project at the University of Vigo In 2008, looking for a project that would be attractive to start working on, my teachers Luis Casáis and Eduardo Domínguez taught me these machines and suggested the great paradigm shift with respect to training with traditional weights in sports where it was necessary braking hard.

What motivated me the most at that time to start researching and working with these devices was that thanks to my experience competing in sailing and the contacts I had from high-level suppliers of pulleys and ropes, those first machines that we saw could already be greatly improved. These components were very basic, and the performance difference in any device when you work with quality components that significantly reduce friction and losses in the application of force are very large.

At that time it was not easy to get an inertial machine in Spain, its price was prohibitive and as I have mentioned its quality is not very good, so I was a bit stuck until talking to my roommate in a regatta, he told me that we can design and manufacture it.

This is how Miguel Riveiro (industrial engineer) got down to work with all the information from the studies we had on flywheels, and we began to work on the design of our first unit. What he insisted the most on and I think was the key to this project was to take care of the details, the circular movement is very sensitive to friction and vibrations and the response of the machine will have a direct relationship with the care we give it. to these details. Miguel gave me the example of bicycles, although they are called the same, you cannot compare the performance of a BH with a basket, perfect for walking, with a bicycle that any professional cyclist uses to try to win the Tour.

Once we had the plans ready, Miguel was clear that the manufacturing had to have very defined quality standards to guarantee the performance of the machine in operation.

From having the first prototype, we began to test, measure, investigate and work with them using as a basis the Training Center that it had in Vigo. We tested the entire R&D process that we were doing at my center and as soon as we had a machine that had certain features, I presented it to my colleagues from the HI20 research group at the University of Vigo, many of whom were already working in professional football This is how the first sales came.

The second key moment came in 2015 when they encouraged me to participate in a business accelerator in which ten projects were going to have financing to carry the business project forward, we presented my project of inertial machines, together with my wife, since I managed to convince her that this project would be the future plan for our life project, and we were selected.

We were able to develop our encoder and our App, develop the one-piece conical shafts…. And endless details that in our passion to compete we understand that they are what make the difference.

RSP is a vital and family project in which our goal is to be able to improve the performance of the athletes who train with our machines, it is a lively and passionate process that requires us to continuously recycle with a very rewarding result to date.

Greetings to all,

Ramón Lago Ruiloba

OUR TEAM

Ramón Lago Ruiloba. CEO of RSP. Product development. Technical advice.

Andrea Valcarce Cividanes. Co-founder of RSP. Marketing, Logistics.

Eduardo Dominguez. RSP Partner. Product validation. High performance consultant.

Our facilities are in Nigrán (Pontevedra), this is where we test and test all the machines, it is our training center, we have all the machines exposed so you can come and test them.