FLYWHEEL TRAINING CON RSP WALL

DISEÑADA PARA ENTRENAR LAS ACCIONES DE TRACCION Y FRENADO DEL TREN SUPERIOR

SOBRE RSP WALL

Nuestra máquina de radio fijo para entrenar las acciones de frenado y de empuje del tren superior. Las máquinas de radio fijo tienen la particularidad de que el eje es el mismo durante todo el recorrido, por lo que todas las variaciones en la aceleración de la máquina, dependen de la capacidad del deportista para aplicar fuerza en ese movimiento.

Tienen una orientación más estructural a nivel muscular al ser máquinas más lentas que una polea cónica y permiten mayor tiempo de tensión al tener una aceleración más baja y por tanto ser movimientos más lentos. Para incidir en esta característica fundamental en las máquinas de radio fijo, se usa la desmultiplicación en la cuerda 1 x 2 que obliga al deportista a aplicar más fuerza y a aumentar el tiempo de tensión durante todo el recorrido del movimiento.

Los movimientos menos acelerados la hacen más sencilla a nivel técnico para personas con poca experiencia en el entrenamiento inercial, siendo esta máquina una gran herramienta para que población no deportista se beneficie del entrenamiento inercial.

¿CÓMO AJUSTAR LA RSP WALL?

Las máquinas de radio Fijo sólo tienen una forma de variar la carga de la máquina y por tanto la respuesta de la máquina ante la misma aplicación de fuerza del deportista:

– Variando el Momento de Inercia: El momento de inercia se define como el valor mínimo de fuerza que el deportista tiene que aplicar para variar el estado de reposo de la máquina, esto significa que cuanto más alto sea este valor, más fuerza tiene que aplicar el deportista para arrancar y parar la máquina, y más tiempo va a necesitar para detener la máquina y volver a arrancarla (más lenta la transición Excéntrica/Concéntrica).

Esto va a significar que a medida que aumentemos el valor de inercia, vamos a aumentar el tiempo de tensión y el valor de fuerza que el deportista pueda aplicar, haciendo el movimiento más lento.

Para profundizar más sobre esto consulta nuestro artículo:

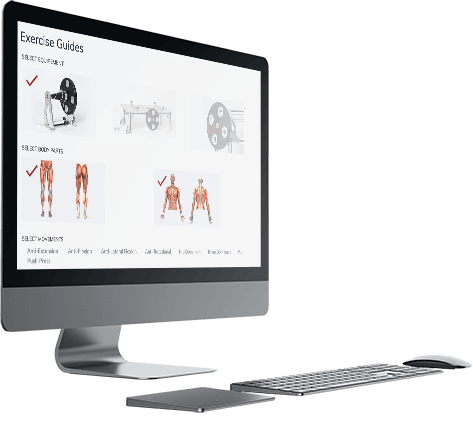

¿CÓMO USAR LA RSP WALL?

Con esta máquina vas a poder realizar todos los movimientos relacionados con la acción de tirar y de empujar del tren superior, para que estos gestos sean lo más eficaces posibles. Es muy importante ajustar bien el recorrido de la cuerda con el movimiento que queremos entrenar, de forma que el final de la fase concéntrica ( punto más alejado) coincida con el tope de la cuerda para mantenerla siempre tensa y evitar que pierda tensión. Para ajustarla o bien nos desplazamos nosotros, acercándonos o alejándonos hasta encontrar este punto, o bien ajustamos la cuerda con el regulador de longitud. También debemos resaltar la importancia de hacer este ajuste en la posición corporal en la queremos hacer ese movimiento ya que toda la musculatura estabilizadora y el tren inferior van a ser determinantes, actuando como fijadores para poder aplicar fuerza y mejorar el rendimiento en esos movimientos.

ESPECIFICACIONES TÉCNICAS

| Medidas: | 28 x 30 x 30 cm de alto. |

| Peso: | 5,5 kg. |

| Accesorios: | – Poleas Alta Carga ( Altas prestaciones con densidades de trabajo elevadas) – Kit de portabilidad – Anclajes para sujetar el Kit de portabilidad a una estructura tipo rack |

| Adaptaciones: | Personalización para trabajos específicos. |

| Repuestos: | – Polea de Chasis – Polea de desmultiplicación 1×2 – Cuerda (4 metros) |

| Ver repuestos y accesorios: |

MOMENTOS DE INERCIA

| Sin masas: | 184,44 Kg/cm² |

| 2 masas: | 221,32 kg/cm² |

| 4 masas: | 258,22 Kg/cm² |

EQUIPAMIENTO DE SERIE

– Chasis RSP Wall

– 2 Cáncamos para variar la altura de la salida de la cuerda

– 1 Cáncamo para tener tiro vertical de la cuerda

– 4 masas de aluminio

– Polea Harken Carbo de 29 mm de diámetro en el chasis

– 2 Poleas Harken Carbo 40 mm de diámetro para la desmultiplicación 1×2

– 4 metros de cuerda de altas prestaciones con regulador de longitud

– Agarre de mano

– Kit de montaje en pared

– Manual de montaje